Cold-Form Blister Packaging Market: A Comprehensive Analysis

Introduction

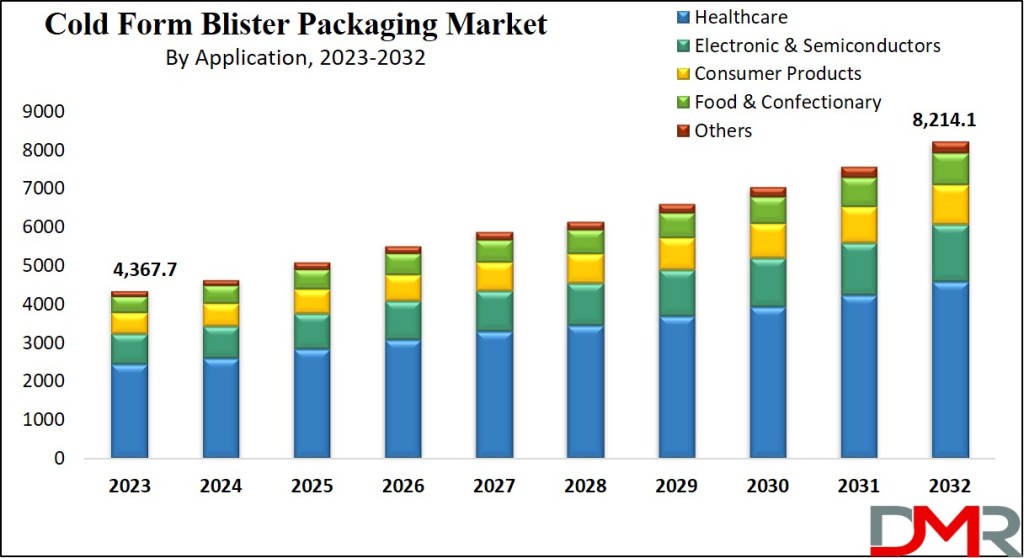

In recent years, the Global Cold-Form Blister Packaging Market has witnessed significant growth, driven by its exceptional features and wide-ranging applications. With a projected valuation of USD 4,367.7 Million in 2023 and an anticipated Compound Annual Growth Rate (CAGR) of 7.3% for the forecast period (2023-2032), this market segment is poised for substantial expansion. Cold-form blister packaging, characterized by its ability to provide complete barrier protection against water, oxygen, light, and moisture, has found extensive usage, particularly in the medical sector for packaging capsules and tablets. The United States market, in particular, is experiencing rapid growth due to its widespread adoption in healthcare packaging.

Get a Free PDF Sample Copy of This Report@ https://dimensionmarketresearch.com/report/cold-form-blister-packaging-market/request-sample

Regulatory measures, such as the Poison Prevention Packaging Act (PPPA) enforced by the Consumer Product Safety Commission (CPSC) in the U.S., mandating child-resistant packaging for OTC and prescription drugs, have further fueled the demand for cold-form blister packaging solutions.

Market Dynamics

Regulatory Influence

Government regulations, such as the Tamper Evident Packaging (TEP) Act enforced by the Food and Drug Administration (FDA), have significantly bolstered the demand for cold-form blister packaging, especially in the pharmaceutical sector. The complex healthcare system in the United States, with multiple intermediaries involved in drug reimbursement and distribution, necessitates secure and efficient packaging solutions. Players like Aptar, a U.S.-based healthcare packaging company, have introduced innovative solutions like Active-Blister healthcare packaging, which received FDA approval for preventing HIV capsules, thus contributing to the growing acceptance of cold-form blister packaging in the pharmaceutical industry.

Rising Pharmaceutical Expenditure

The escalating expenditure on prescription and generic drugs in the United States compared to other countries like Germany, the UK, and Australia indirectly impacts the growth of the cold-form blister packaging market. Increased consumer spending on these drugs translates to a higher demand for blister packs, primarily used for solid unit dose medications such as tablets, capsules, and pills. Consequently, pharmaceutical companies and packaging manufacturers are focusing on meeting the packaging needs of the sector, thus driving market growth.

Key Takeaways

- Market Growth Projection: The Global Cold-Form Blister Packaging Market is poised to reach a valuation of USD 4,367.7 Million by 2023, with a projected CAGR of 7.3% during the forecast period from 2023 to 2032.

- Characteristics Driving Growth: Cold-form blister packaging offers comprehensive barrier protection against water, oxygen, light, & moisture. Its utilization of cold-forming foil eliminates the need for heat during the packaging process, making it ideal for various products, particularly in the medical sector.

- Regulatory Influence: Regulatory measures, such as the Poison Prevention Packaging Act (PPPA) in the U.S., mandate child-resistant packaging for OTC and prescription drugs, thereby fueling the demand for cold-form blister packaging solutions.

- Market Dynamics: The market is bolstered by policies like the Tamper Evident Packaging (TEP) Act, which enhance demand, particularly in the pharmaceutical sector. Moreover, factors such as the complex U.S. healthcare system and increasing expenditure on prescription drugs contribute to market growth.

Recent Developments in the Cold Form Blister Packaging Market (2023-2024):

- 2023: The global cold form blister packaging market reached an estimated value of USD 4.11 billion, showcasing continuous growth.

- 2024: Rising demand for pharmaceuticals, including medications and vaccines, fuels market expansion. This surge is attributed to an aging population and increasing healthcare awareness.

- 2023: Focus on sustainable solutions like recyclable materials and eco-friendly production processes gains momentum. Amcor Plc developed the first recyclable retort flexible packaging in 2020, contributing to this trend.

Buy This Exclusive Report Here@ https://dimensionmarketresearch.com/checkout/cold-form-blister-packaging-market

Research Scope and Analysis

By Material

Aluminum Dominance

- Aluminum emerges as the dominant material segment in 2023, capturing the maximum share. Its superiority lies in its barrier effectiveness, which prevents contamination and extends the shelf life of products by obstructing oxygen and moisture ingress. Additionally, aluminum ensures the stability and efficacy of medical products, including capsules and over-the-counter drugs, thereby propelling market growth.

Expansion of PVC

- The segment of PVC is expected to witness further expansion in the coming years. Known for its cost-effectiveness and high visibility characteristics, PVC is an ideal choice for cold-form blister packaging, especially for items with lower price points. Its versatility makes it suitable for a wide range of applications.

By Application

Healthcare Dominance

- The healthcare segment commands the largest market share, driven by the utilization of composite plastic and aluminum film materials in packaging. Cold-form blister packaging offers superior product protection compared to thermoformed plastics, ensuring increased protection against contamination, physical damage, and tampering. This segment's dominance underscores the importance of efficacy and safety in packaging pharmaceutical products.

Consumer Goods Growth

- The segment of consumer goods is expected to witness significant growth from 2023 to 2032, fueled by the increasing demand for items like lipsticks, bar soaps, toothbrushes, and shower gels. Transparent plastic film materials used in cold-form blister packaging enhance product visibility, contributing to market growth in this segment.

Market Material-Share Analysis

The materials used in cold-form blister packaging include aluminum, PVC, polypropylene (PP), polyethylene (PE), polyethylene terephthalate (PET), and oriented polyamide. Each material offers distinct advantages, catering to diverse packaging needs across various industries.

Regional Analysis

Asia Pacific Dominance

- The Asia Pacific region emerges as the dominant force in the cold-form blister packaging market, accounting for a maximum share of 33.2% in 2023. The region's dominance is attributed to the burgeoning healthcare and medical sectors, coupled with the increasing trend of online platforms. Community pharmacies favor cold-form blister packs for their ease of handling, space efficiency, and product visibility. Online platforms like Amazon prioritize the use of such packaging for medical items due to its compactness and safety during transportation, further fueling market growth.

Prominent Players

The Global Cold Form Blister Packaging Market is characterized by the presence of several key players, including:

- Bemis Company Inc.

- Constantia Flexibles

- Amcor plc

- WINPAK Ltd.

- Uflex Limited

- Sonoco Products Company

- Bilcare Research

- Tekni-Plex

- Essentra plc

- ACG

- Wasdell Group

- Other Key Players

FAQs

1. What is cold-form blister packaging?

Cold-form blister packaging is a type of packaging that utilizes cold-forming foil, eliminating the need for heat during the packaging process. It provides complete barrier protection against water, oxygen, light, and moisture, making it ideal for various industries, including pharmaceuticals.

2. Why is cold-form blister packaging preferred in the pharmaceutical sector?

Cold-form blister packaging is preferred in the pharmaceutical sector due to its ability to provide secure and tamper-evident packaging, ensuring the integrity of medications. Regulatory measures, such as the Poison Prevention Packaging Act, mandate the use of child-resistant packaging for OTC and prescription drugs, further driving its adoption.

3. Which material dominates the cold-form blister packaging market?

Aluminum emerges as the dominant material in the cold-form blister packaging market due to its barrier effectiveness, which prevents contamination and extends the shelf life of products. Additionally, aluminum ensures the stability and efficacy of medical products, making it a preferred choice in pharmaceutical packaging.

4. What are the key factors driving the growth of the cold-form blister packaging market?

The growth of the cold-form blister packaging market is primarily driven by regulatory measures, rising pharmaceutical expenditure, and the dominance of the healthcare segment. Government regulations, such as the Tamper Evident Packaging Act, enhance the demand for secure packaging solutions, while increased spending on prescription and generic drugs fuels market growth.

5. Which region dominates the cold-form blister packaging market?

The Asia Pacific region dominates the cold-form blister packaging market, driven by the burgeoning healthcare and medical sectors, coupled with the increasing trend of online platforms. Community pharmacies and online platforms prioritize the use of cold-form blister packaging for its efficiency and product visibility.

Conclusion

The Global Cold-Form Blister Packaging Market is experiencing robust growth, driven by its superior barrier protection and diverse applications across industries. Regulatory measures, rising pharmaceutical expenditure, and the dominance of the healthcare segment are key factors propelling market expansion. With innovative solutions and a focus on meeting evolving packaging needs, the market is poised for continued growth in the coming years.

Comments (0)