Flame Retardants for Aerospace Plastics Market: Ensuring Safety in the Skies

In the realm of aerospace engineering, safety is paramount. One critical aspect of ensuring safety in aircraft design involves addressing the combustibility of plastic materials used in various components. The integration of flame retardants has emerged as a crucial solution to mitigate fire hazards and enhance security measures, particularly in enclosed spaces like airplane cabins. The Flame Retardants for Aerospace Plastics Market plays a pivotal role in providing these essential additives to the aerospace industry, ensuring the safety and security of travelers worldwide.

Understanding Market Growth Trends

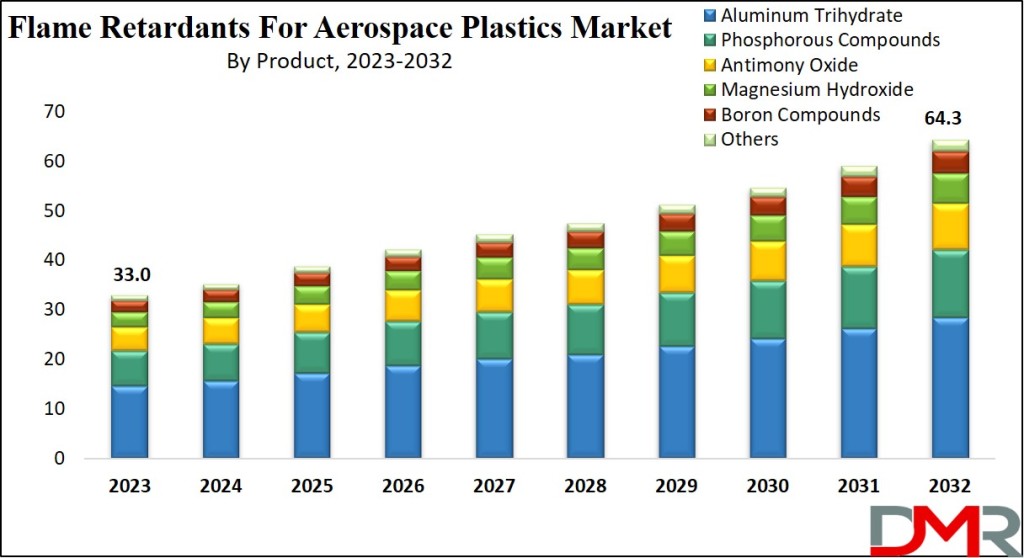

The Global Flame Retardants for Aerospace Plastics Market witnessed significant growth in recent years and is poised for further expansion. In 2023, the market reached a value of USD 33.0 million and is projected to maintain a steady Compound Annual Growth Rate (CAGR) of 7.7% throughout the forecast period (2023-2032). This growth is primarily attributed to the increasing demand for flame retardants driven by security concerns related to plastic combustibility in aerospace applications.

Get a Free Sample Copy of This Report @ https://dimensionmarketresearch.com/report/flame-retardants-for-aerospace-plastics-market/request-sample

Factors Driving Market Expansion

- Security Concerns: With a heightened focus on safety and security in the aerospace industry, the demand for flame retardants has surged to mitigate fire risks associated with plastic materials.

- Regulatory Compliance: Stringent regulations set forth by regulatory bodies like the FDA and EPA necessitate the use of flame retardants in aerospace plastics, further driving market growth.

- Technological Advancements: The adoption of advanced composite materials, such as Carbon Fiber Reinforced Polymers (CFRP) and Glass Reinforced Plastics (GRP), in aircraft construction has propelled the demand for flame retardants to ensure fire resistance.

Market Dynamics in North America

In North America, particularly the United States, the demand for flame retardants in aerospace plastics is notably high. The region accounts for a significant market share, driven by robust demand from packaging, automotive, and aerospace sectors. Moreover, stringent regulatory standards imposed by authorities like the FDA and EPA contribute to market growth, particularly in industries emphasizing environmental and consumer safety.

Market Drivers in North America

- Industrialization: The rapid pace of industrialization in countries like Mexico fuels market expansion by increasing consumer disposable income and driving demand for flame retardants.

- Awareness and Safety Measures: Heightened awareness regarding fire risks in aerospace applications necessitates the adoption of flame retardants, further boosting market demand.

Recent Developments in Flame Retardants for Aerospace Plastics Market (2023-2024):

Growing Market:

- The market size is expected to reach USD 50.18 million by 2030, growing at a CAGR of 7.0% from 2023 to 2030.

- Increased demand for lighter aircraft: Plastics offer weight savings, boosting fuel efficiency and driving their use in airframes and interiors.

- Stringent fire safety regulations: Growing concerns about flammability necessitate effective flame retardants.

- Rise in commercial aircraft production: Expanding fleets in developing countries like India create demand for flame-retardant plastics.

Key Takeaways:

- Market Growth: The Flame Retardants for Aerospace Plastics Market is experiencing steady growth, driven by increasing security concerns and stringent regulatory standards in the aerospace industry.

- Product Trends: Aluminum trihydrates and organic phosphorous compounds are dominant in the market, offering cost-effectiveness and widespread availability for aerospace applications.

- Polymer Utilization: Carbon Fiber Reinforced Polymers (CFRP) and Glass Reinforced Plastics (GRP) are prominent in aerospace construction, contributing to reduced aircraft density and enhanced safety.

- Regional Dynamics: Europe leads the market, propelled by the presence of major aerospace companies and regulatory frameworks promoting non-halogenated retardants.

Buy This Exclusive Report Here@ https://dimensionmarketresearch.com/checkout/flame-retardants-for-aerospace-plastics-market

Research Scope and Product Analysis

Dominant Products in the Market

Aluminum trihydrates emerge as the dominant segment in the Global Flame Retardants for Aerospace Plastics Market. Their widespread availability and cost-effectiveness make them a preferred choice for aerospace polymer applications. Additionally, organic phosphorous compounds, antimony oxide, and ammonium polyphosphate witness rapid growth due to increased demand for fire-retardant coatings and polyamides in aerospace plastics.

Polymer Utilization Trends

CFRP holds a significant share in the polymer segment, attributed to its remarkable properties such as reduced aircraft density and exceptional impact resistance. Major aerospace companies, including Airbus and Boeing, increasingly incorporate CFRP in aircraft production to enhance performance and safety standards. GRP also gains traction for its weight reduction benefits and improved airflow properties, contributing to the overall advancement of the aerospace plastics market.

Regional Analysis and Market Leadership

Europe dominates the Flame Retardants for Aerospace Plastics Market with a substantial share of 48.4% in 2023. Key factors driving Europe's market leadership include the presence of major aerospace companies like Boeing and Airbus, stringent regulatory frameworks promoting non-halogenated retardants, and technological innovations in aircraft manufacturing.

Prominent Market Players

Several key players contribute to the growth and innovation in the Global Flame Retardants for Aerospace Plastics Market. Companies such as Clariant, Huber Engineered Materials, and BASF SE are at the forefront of developing advanced flame retardant solutions tailored to aerospace applications, ensuring safety and compliance with regulatory standards.

FAQs (Frequently Asked Questions)

1. What drives the demand for flame retardants in aerospace plastics?

- Answer: The demand is primarily driven by security concerns related to plastic combustibility in aircraft components and stringent regulatory standards imposed by authorities like the FDA and EPA.

2. Which region holds the largest market share in the Flame Retardants for Aerospace Plastics Market?

- Answer: Europe dominates the market, accounting for 48.4% of the global market share in 2023.

3. What are the dominant products in the flame retardants market for aerospace plastics?

- Answer: Aluminum trihydrates and organic phosphorous compounds are among the dominant products, owing to their cost-effectiveness and widespread availability.

4. How do carbon fiber reinforced polymers (CFRP) contribute to market growth?

- Answer: CFRP offers exceptional properties such as reduced aircraft density and enhanced impact resistance, making them a preferred choice for aircraft construction and driving market growth.

5. Which companies are prominent players in the Flame Retardants for Aerospace Plastics Market?

- Answer: Key players include Clariant, Huber Engineered Materials, BASF SE, and other leading manufacturers dedicated to developing innovative flame retardant solutions for aerospace applications.

Conclusion

The Flame Retardants for Aerospace Plastics Market plays a pivotal role in ensuring safety and security in the aerospace industry. With the demand for flame retardants expected to witness steady growth, driven by technological advancements and regulatory compliance, market players are poised to capitalize on opportunities for innovation and market expansion. By addressing the evolving needs of the aerospace sector, the industry can continue to enhance safety measures and mitigate fire risks, thereby ensuring the well-being of travelers worldwide.

Comments (0)