The web guide control system is intended to solve the problem of material deviation or equipment deviation. The coil’s position is always tracked and corrected in real time during the manufacturing process. Without manual intervention, production can be ensured and improved.

Web Guide Control System Composition

A web guiding controller, a web guide sensor and a guide frame comprise the web guide control system.

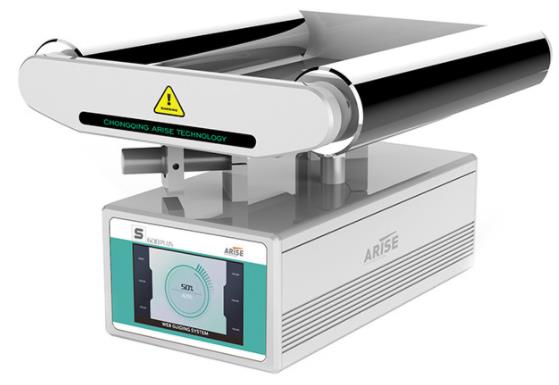

Web Guide Controller

The core component of the guiding system is the web guide controller. The Arise web guide controller is simple to use, elegant in appearance and has a high level of system accuracy.

Web Guide Sensor

Arise web guide sensor has the advantages of high precision, fast reaction time, and a wide range of materials.

Web Guide framework

Arise web guiding frame can meet the needs of various product production lines in the industry. It has the benefits of easy installation, simple operation, and a good appearance.

Classification Of Web Guide Control System

The power equipment of the EPC web guiding system is classified into four types: electromechanical, electrohydraulic, pneumatic, and magnetic. The following figure depicts the structural principle of the electro-hydraulic EPC web guide system.

The sensors in the three control systems are similar in structure, including infrared sensors, reflective infrared sensors, ultrasonic sensors, digital sensors, pneumatic sensors, laser sensors, and camera sensors, which include electromechanical and electrohydraulic sensors. It is primarily used in infrared and ultrasonic sensors.

Electromechanical and electrohydraulic web guiding systems are also equipped with a powerful and easy-to-use controller. When the film is produced at high speeds, it has a high dynamic response level and detection accuracy. It can be remotely and in real time monitored. control.

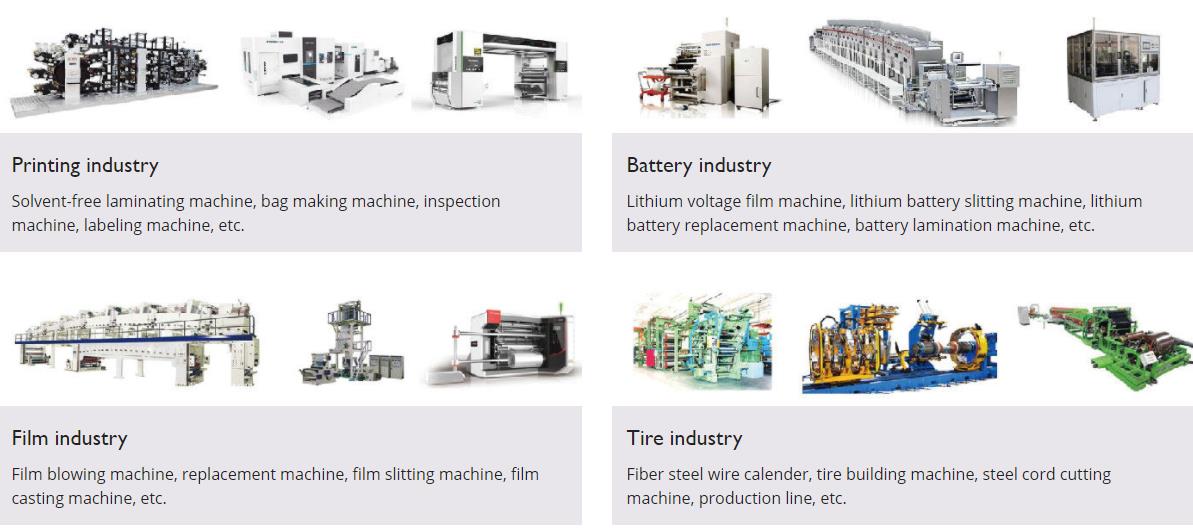

Wide Applications Of Web Guide Control System

Tire, Rubber Industry

The ultimate goal of the web guide system in the tire industry is to guide the material offset and ensure that the material is in the proper position to meet the needs of the production process. The rectification control system can be used on a variety of machines, including extrusion linkage, inner liner/film roll, curtain calender, cutting machine, and molding machine, but the specific methods and applications vary by machine.

Lithium and New Energy Industry

In the lithium-ion coating and slitting industry, the pole piece appears to be deviated in the continuous rolling production line of the battery pole piece due to mechanical errors in the unit, deviation of the guide rod, vibration, and fluctuation of the pole piece tension. It makes the pole piece vulnerable to damage during the rolling process, compromising product quality and economic benefits, and the tower type roll phenomenon frequently occurs during the winding process.

Arise guide system effectively overcomes these issues and is at the forefront of the industry. The sensor detects the offset of the material. After comparing the operation, the controller sends the action command to the driver in a very short time, ensuring that the material can run along the specified line in the mechanical work, and the correction accuracy can reach 0.1mm, fully meeting the customer’s accuracy requirements.

Hygiene Products Industry

Arise is dedicated to providing complete solutions for the sanitary products industry. Its main products, which include sanitary napkins, baby pants, pants, pet mats, and so on, are widely used in sanitary napkins, baby pants, pants, and so on. It has been well received by users and is at the forefront of the market with high cost performance on the production equipment, and with its exquisite appearance, simple operation, and humanized service. To meet the high-speed production requirements of sanitary equipment, the number of web guides has increased, becoming an important component of sanitary equipment.

Bidirectional Stretching Equipment

The use of a web guiding control system in the production line of biaxially stretched plastic film is undeniably successful. It greatly reduces the likelihood of problems such as cross-clip, wrinkle, film rupture, and ripple jitter occurring, and it enables high-speed and high-efficiency film production.

As a leading web guide control system manufacturer, Arise is committed to providing a perfect solution, which includes web guiding equipment, web tension controller, and web guide sensor, which have been widely used in various industries.

Comments (0)