Web guiding systems play a crucial role in facilitating the seamless movement of materials through the manufacturing process in high-speed printing, where precision is of utmost importance. However, the accelerated pace of printing operations introduces new challenges that demand innovative solutions. This article explores the hurdles faced by web guiding systems in high-speed printing and delves into the solutions that pave the way for improved accuracy and efficiency.

Challenges in Web Guiding for High-Speed Printing

Dynamic Tension Variations

High-speed printing processes often lead to dynamic tension fluctuations in the web, impacting material alignment and registration.

Substrate Variability

Variations in printing substrates and materials, including differences in elasticity and thickness, make consistent web guiding at high speeds challenging.

Accurate Registration Requirements

Perfect color and element registration are essential when printing at high speeds, presenting a significant challenge in maintaining proper alignment throughout the process.

Web Flutter and Deflection

Increased speeds may cause the web to experience flutter or deflection, introducing deviations that must be swiftly detected and corrected by the web guiding system.

Vibration and Machine Dynamics

Vibrations and dynamic motions of high-speed printing equipment can influence the web's stability, complicating the challenge of keeping it aligned.

Material Stretch and Shrinkage

High speeds and associated forces can cause materials to stretch or shrink, impacting the accuracy of web guiding systems and necessitating real-time adjustments.

Solutions to Address Web Guiding Challenges in High-Speed Printing

Advanced Sensor Technologies

Utilizing cutting-edge sensor technologies like ultrasonic or laser sensors enables real-time monitoring of web position and tension, allowing rapid adjustments to changes in material properties.

Closed-Loop Control Systems

Continuous analysis of sensor feedback by closed-loop control systems ensures real-time adjustments to the web guiding mechanism, maintaining precise alignment despite dynamic tension variations.

Smart Algorithms for Registration Control

Employing smart algorithms predicting and compensating for registration errors ensures accurate web alignment throughout the printing process, contributing to high-quality output.

Web Guiding Systems with Fast Response Times

Investing in systems with rapid response times ensures swift corrections, minimizing the impact of flutter, deflection, or sudden changes in web behavior.

Dynamic Tension Control Mechanisms

Incorporating tension control mechanisms that dynamically adjust to changes in web tension helps preserve stability, especially in settings where tension fluctuations are common.

Continuous Monitoring and Diagnostics

Implementing continuous monitoring and diagnostics through modern Human-Machine Interface (HMI) systems enables operators to identify potential issues before they affect print quality, reducing downtime.

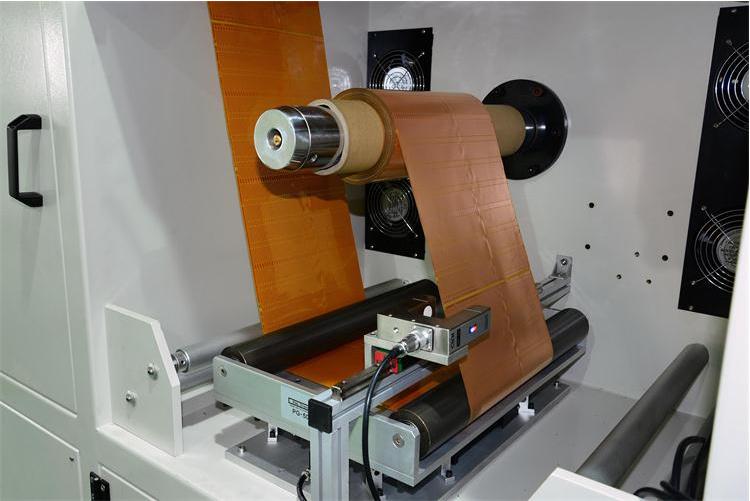

Precision Rollers and Guiding Components

Upgrading precision-engineered rollers and web guiding components reduces friction, enhancing the overall stability of the system and mitigating the impact of vibrations and dynamic forces.

Material-specific Web Guiding Configurations

Tailoring configurations to the individual qualities of different substrates ensures the system can respond to variations in elasticity and thickness, resulting in improved performance.

Conclusion

Web guiding in high-speed printing is a delicate balance of precision and speed. Addressing the challenges posed by the rapid pace of modern printing requires the adoption of innovative technology, smart algorithms, and sensitive control systems. As the demand for high-quality, high-speed printing grows, the industry's ability to tackle these issues becomes increasingly crucial for achieving peak performance and producing flawless prints. By focusing on adaptable solutions and continuous innovation, web guiding systems can meet the challenges of high-speed printing with unparalleled accuracy and efficiency.

Comments (0)