As HVAC systems evolve to meet stringent energy and environmental standards, microchannel coil technology emerges as a game‑changer. Leveraging precision‑engineered aluminum fins and flat multi‑port tubes, these coils deliver unparalleled heat‑transfer efficiency across three key interfaces. In this article, an HVAC veteran’s perspective will unpack the science behind these advances and illustrate how they yield 20–40% system gains over legacy finned‑tube coils.

Enhanced Air‑Side Turbulence Management

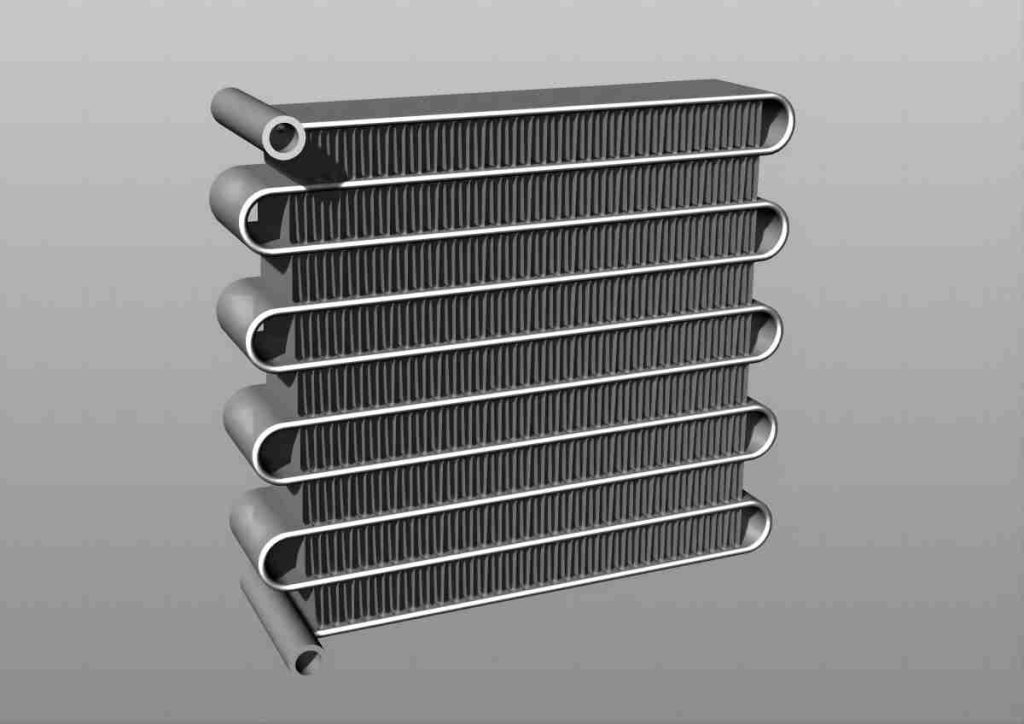

One pillar of microchannel success lies in the fin pack’s aerodynamic design. Instead of passive, widely spaced fins, microchannel coils employ tightly arrayed, chemically treated aluminum profiles that induce micro‑turbulence. The result is a lower pressure drop for equivalent airflow rates, ensuring each cubic meter of air absorbs maximum heat with minimal fan power expenditure.

Seamless Fin‑to‑Tube Contact for Superior Conduction

Conventional round tubes often touch fins at discrete points, leading to localized thermal bottlenecks. By contrast, microchannel coils use flat, brazed tubes that run continuously along the fin’s base. This broad, intimate bond slashes interface resistance, facilitating an even temperature gradient and boosting conduction—even under part‑load or low‑delta‑T scenarios where traditional coils falter.

Multi‑Port Tube Dynamics for Accelerated Refrigerant Heat Exchange

Inside each flat tube, multiple slender refrigerant channels replace single‑pass designs, creating higher flow velocities and repeated phase‑change events. These micro‑passages maximize surface‑area exposure and convective coefficients, so refrigerant picks up or rejects heat more rapidly. The net effect is a faster coil response and tighter control over evaporating and condensing pressures.

Quantifiable Efficiency Breakthroughs

When these three enhancements converge, microchannel coils routinely demonstrate 20–40% improvements in coefficient of performance (COP) and seasonal energy efficiency ratio (SEER). In real‑world installations—from rooftop packages to chillers—this translates into lower kWh consumption, smaller chiller footprints, and reduced refrigerant charge. Over a typical equipment life span, the energy savings alone can offset incremental capital costs.

Field Applications and ROI

Long‑term case studies in commercial offices and light industrial facilities underscore rapid payback periods of 2–4 years. Retrofitting existing finned‑tube banks with microchannel bundles has proven especially cost‑effective, delivering immediate efficiency boosts without full system replacement.

Conclusion

Drawing on decades of hands‑on engineering and empirical testing, microchannel coil technology https://www.kaltra.com/microchannel-coils represents a mature, high‑performance solution for cutting‑edge HVAC design. For engineers and facility managers aiming to meet tomorrow’s energy codes today, these coils offer a clear pathway to dramatic efficiency gains, lower operational expenses, and smaller environmental footprints.

Comments (0)