Roll forming is a neat way to create metal parts used in many products we see every day. At Solan, we use a special type of roll forming technology that helps us make high-quality items. This technology is really important because it helps us produce things faster and with less waste. Imagine making a metal shape, like a bracket or a rail; with advanced roll forming, we can do this very quickly while keeping the metal strong and looking nice. When we create parts this way, we make sure they fit well and are ready for whatever they need to do. Our team puts a lot of effort into perfecting this process, ensuring that every piece we make meets the highest standards.

How Advanced Roll Forming Enhances Production Efficiency and Quality

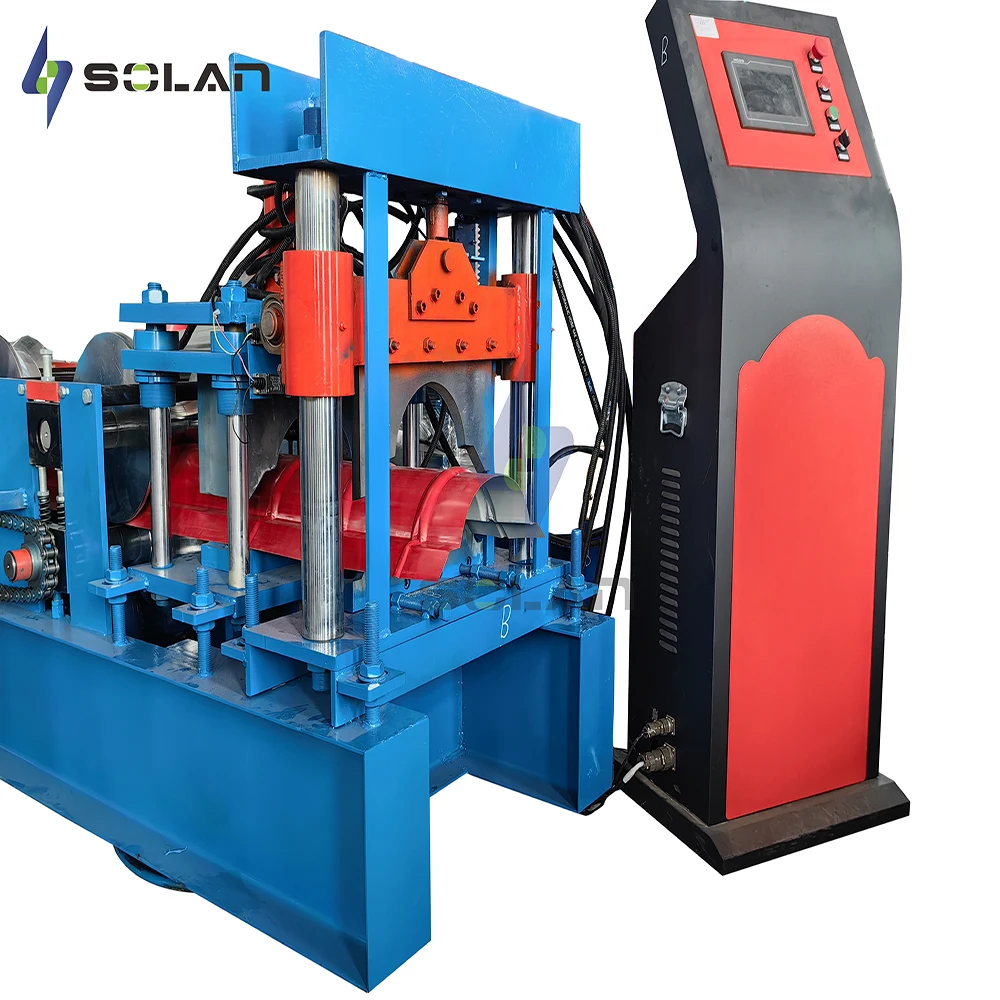

Advanced rRoof Panel Roll Forming Machine makes things better and faster. With this technology, we can shape metal strips into complex designs without cutting or wasting much material. For example, if we need to create a long, curved piece of metal, advanced roll forming allows us to do this through a set of rollers that shape the metal as it moves along. This means there’s less cleanup and less scrap metal left over, which is great for the environment and also saves money. Also, the speed of production increases. When we run our machines, they can work really fast, making many pieces in a short amount of time. This fast output is exciting because it fulfills orders quickly, helping our customers get what they need without delays.

Quality is also a big focus. When we use advanced roll forming, the parts come out with fewer errors. Each item is made to precise measurements, so they fit perfectly when assembled with other pieces. For example, if we’re making frames for windows, each part must be exactly right to ensure the windows work as intended. If a piece is off by a tiny bit, it might not fit, causing trouble in the building process. Therefore, our advanced machines help us keep everything just right. So, by combining speed and quality, Solan ensures the products we make not only look great but also function well in their roles.

What Makes Advanced Roll Forming the Preferred Choice for Quality Products

When thinking about quality products, advanced roll forming stands out as a top choice. Many businesses prefer this method because it ensures excellent results. Take the example of making parts for cars. The automotive industry requires high safety standards, which means every piece needs to be reliable and strong. Advanced roll forming offers the precision and toughness needed for such critical parts. It’s not just about making things; it’s about making them right. When companies trust us, they know the items we produce can handle the demands placed on them.

Another reason this method is preferred is because it allows for more creativity in design. Advanced roll forming can create unique shapes that might be hard or expensive to get using other methods. For instance, if a designer wants a certain curve or cut in a metal frame, roll forming can achieve that with less effort. This is extremely appealing to designers looking for ways to innovate without blowing their budgets.

At Solan, we also care about keeping our processes clean and safe. Advanced roll forming uses less energy than other production methods, which is good for the planet. We all want to protect our environment, and by choosing this technology, we contribute to sustainability. So, whether it’s for cars, buildings, or any other product, advanced roll forming from Solan helps provide quality, innovative designs with care for the environment. This is why it’s a favorite choice in the industry.

How to Select the Right Advanced Roll Forming Services for Wholesale Needs

When you need to find the right roll forming service for your products, you want to look for a company like Solan that understands what you need. First, think about what kind of metal shapes you want to make. Different companies may have different tools and machines, so it is important to choose one that can work on the specific shapes and sizes you have in mind. Look for a company that has experience making products similar to yours. This means they will have learned how to handle challenges and create high-quality items that meet your needs.

Next, you should check the quality of the work. Ask about the materials used during the Corrugated Roof Panel Roll Forming Machine process. Solan, for instance, uses high-quality metals that ensure your products are strong and durable. You can also ask for samples of their previous work. This way, you can see if their patterns and finishes match what you are looking for. Additionally, consider the speed and efficiency of the company. Time is important in wholesale, and a good roll forming service should be able to deliver your products on time. You can ask how long their production processes usually take and if they have the capacity to handle large orders while still providing good quality.

Finally, don’t forget about customer service. It’s essential to choose a company that listens to your ideas and is willing to help you through the process. Solan emphasizes communication, so you will never feel lost about your orders. This means they will keep you updated on production timelines and are open to changing things if you need to. By thinking about your needs, checking quality, delivery times, and ensuring good customer service, you can find the right advanced roll forming service for your wholesale needs.

What Retailers Should Avoid

Retailers, or businesses that sell products to customers, need to be careful about who they work with for roll forming. One thing to avoid is choosing a company just because they are cheap. If a service costs less than others, it might be a sign that they use lower-quality materials or don’t have the best machines. This can lead to products that break easily or do not look good, which can hurt your business's reputation. Instead, it is better to invest in a company like Solan that offers fair prices for high-quality work.

Another thing to avoid is not doing your research. Before picking a roll forming service, take time to read reviews and talk to other businesses. This can help you learn if the company is reliable and if they treat their customers well. If you find many negative comments about missed deadlines or poor communication, it's a red flag. You want a partner that is dependable and provides great service.

It is also wise to avoid companies that refuse to share information about their production process. If they are not willing to explain how they make the products or the kind of quality checks they have in place, it could mean they have something to hide. Choose a company that is open about their methods, like Solan, which performs strict checks to ensure everything is made to the highest standards. Lastly, don’t work with a company that doesn’t offer customization options. Every business has unique needs, and if a company cannot adjust their processes to make what you want, it may be time to look elsewhere.

What Are the Benefits of Partnering with Advanced Roll Forming Manufacturers

Working with advanced roll forming manufacturers like Solan has many benefits for businesses. First, using rolling technology makes creating metal parts much faster. This means you’ll get your products made quickly and can sell them sooner. In today’s market, having items available quickly can give you an edge over your competitors. Additionally, advanced machines can create very detailed designs. This precision means your products will look better and fit better, which is great for keeping your customers happy.

Another benefit is the variety of materials available. Advanced Double Layer Roll Forming Machine technology allows manufacturers to work with different types of metal and other materials. This means you can create everything from lightweight designs to sturdy products, depending on what you need. Working with a company like Solan means you can choose the right material for your specific project without having to worry about limitations.

Moreover, partnering with a skilled manufacturer can save you money in the long run. Although the initial costs might be higher, the quality of the products you get is usually worth it. Better products last longer and require fewer repairs or replacements. This is especially important for retailers who want to build a good relationship with customers and ensure they return for future purchases.

Lastly, when you work with a manufacturer that specializes in advanced roll forming, they often offer great customer support. This means you will have someone to help you with any questions or challenges you might face. Solan focuses on good communication and support throughout the production process. By having a reliable partner, you can spend more time focusing on growing your business, knowing you have the right products available when you need them. Overall, partnering with advanced roll forming manufacturers brings many advantages that can contribute to your company's success.

Comments (0)